- ● Particle size/specification: Customized to customer requirements.

- ● Package: Ton bags or according to customer requirements.

- Description

- Product specifications

- Application

Description

Adding silicon, calcium and manganese in steelmaking can desulfurize and purify molten steel. Its main characteristics are strong deoxidation ability, which can improve the fluidity of molten steel and solve the problem of nodules in continuous casting nozzles; the desulfurization effect is obvious when combined with desulfurization materials; purify molten steel, reduce impurities in steel, and improve steel quality; replace high-priced deoxidation materials such as silicon aluminum and ferrosilicon, and increase alloy recovery rate by 10%~20%.

Product specifications

| Element | Content |

|---|---|

| Si | 20% |

| Mn | 7% |

| Ca | 30% |

| S | 0.1 - 0.2% |

| P | 0.1% |

| Granularity | 10 - 50mm |

Application

Silicon calcium is a binary alloy composed of silicon and calcium, which belongs to the category of ferroalloys. Its main components are silicon and calcium, and it also contains impurities such as iron, aluminum, carbon, sulfur and phosphorus in varying amounts. It is used as a calcium additive, deoxidizer, desulfurizer and modifier for non-metallic inclusions in the steel industry. It is used as an inoculant and modifier in the cast iron industry.

Since calcium has a strong affinity with oxygen, sulfur, hydrogen, nitrogen and carbon in molten steel, silicon calcium alloy is mainly used for deoxidation, degassing and sulfur fixation of molten steel. Silicon calcium produces a strong exothermic effect after being added to molten steel. Calcium turns into calcium vapor in molten steel, which stirs the molten steel and is beneficial to the floating of non-metallic inclusions. After deoxidation of silicon calcium alloy, non-metallic inclusions with larger particles and easy to float are produced, and the shape and properties of non-metallic inclusions are also changed. Therefore, silicon calcium alloy is used to produce clean steel, high-quality steel with low oxygen and sulfur content, and special performance steel with extremely low oxygen and sulfur content. Adding silicon calcium alloy can eliminate the problems of nodules in the ladle nozzle of steel using aluminum as the final deoxidizer, and the blockage of the nozzle of the intermediate tank in continuous steel casting and ironmaking. In the steel refining technology outside the furnace, silicon calcium powder or core wire is used for deoxidation and desulfurization to reduce the oxygen and sulfur content in the steel to a very low level; it can also control the sulfide form in the steel and improve the utilization rate of calcium. In cast iron production, silicon calcium alloy has not only deoxidation and purification effects, but also a nucleation effect, which helps to form fine or spherical graphite; make the graphite in gray cast iron evenly distributed and reduce the tendency of white cast iron; and can increase silicon, desulfurize, and improve the quality of cast iron.

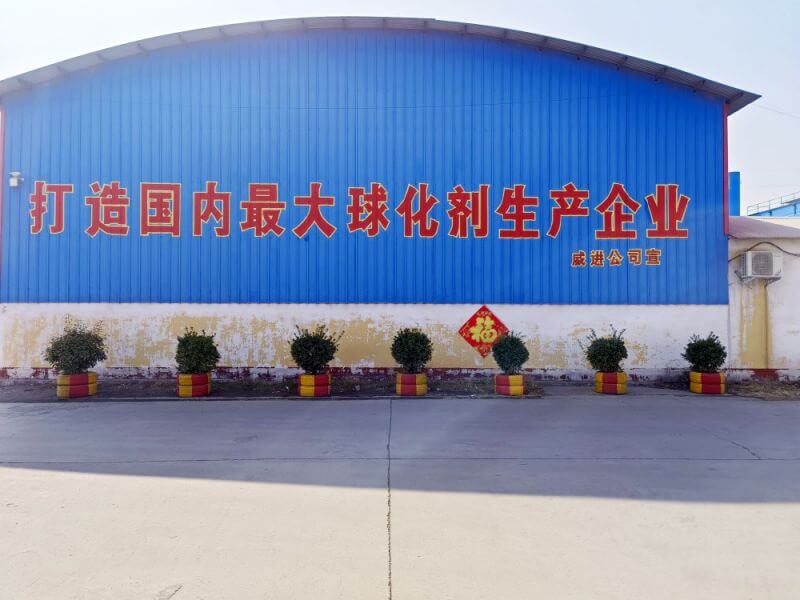

Why Choose Us

-

01Strong technical skillsWe have over 10 years of industry knowledge in the fields of steelmaking, casting of ferroalloys, and processing of core wire products.

-

02Customized manufacturingEngaged in the processing of ferrosilicon, spheroidizing agents, inoculants, deoxidizers, and other steelmaking, casting ferroalloys, and core wire products.

-

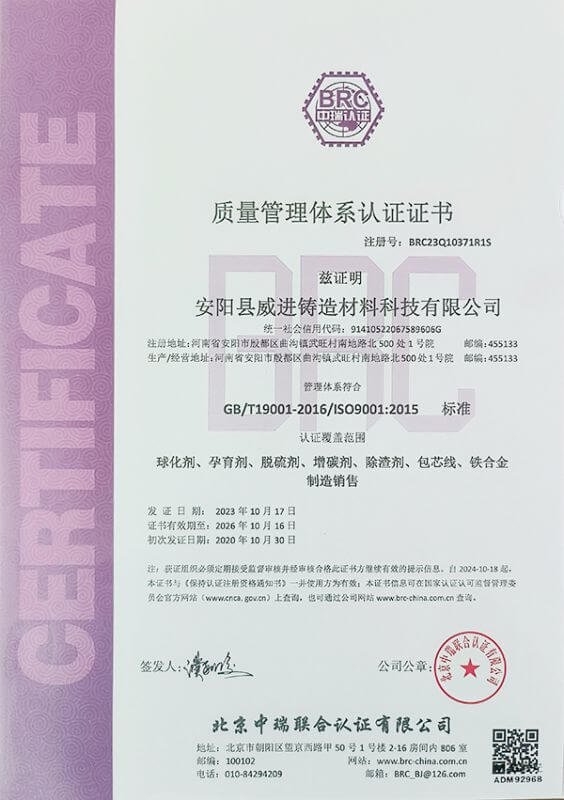

03Quality AssurancePassed ISO9001-2015 quality system certification, strictly controlled product quality, and produced strictly according to customer requirements.

-

04Serving the worldA ferroalloy export license enterprise approved by the Ministry of Commerce, with a complete range of products, meeting demand, mature logistics, and customers worldwide.

Qualification

-

Do you provide samples?Yes, we can provide samples. Samples are free, freight is inevitable, special cases will be handled specially.

-

What is the minimum order quantity?It depends on the project. The minimum order quantity for general products is one ton.

-

How is the quality of our products?An ferroalloy export license enterprise approved by the Ministry of Commerce, with a complete range of products to meet demand, mature logistics, and customers all over the world.

-

What industries does WeiJin serve?Provide various shaped and unshaped refractory products for metallurgy, nonferrous metals, building materials, chemicals, power boilers and other industries.

-

What can WeiJin do?Our R&D team and professional engineers will analyze the damage mechanism of different equipment, recommend products suitable for the use environment, and find the causes and solve the problems that arise during use.

-

Can WeiJin provide products with special specifications or sizes?A strong R&D team and a full set of testing equipment not only lay a solid foundation for the production of customized specifications, but also for the production of products of different sizes and shapes.