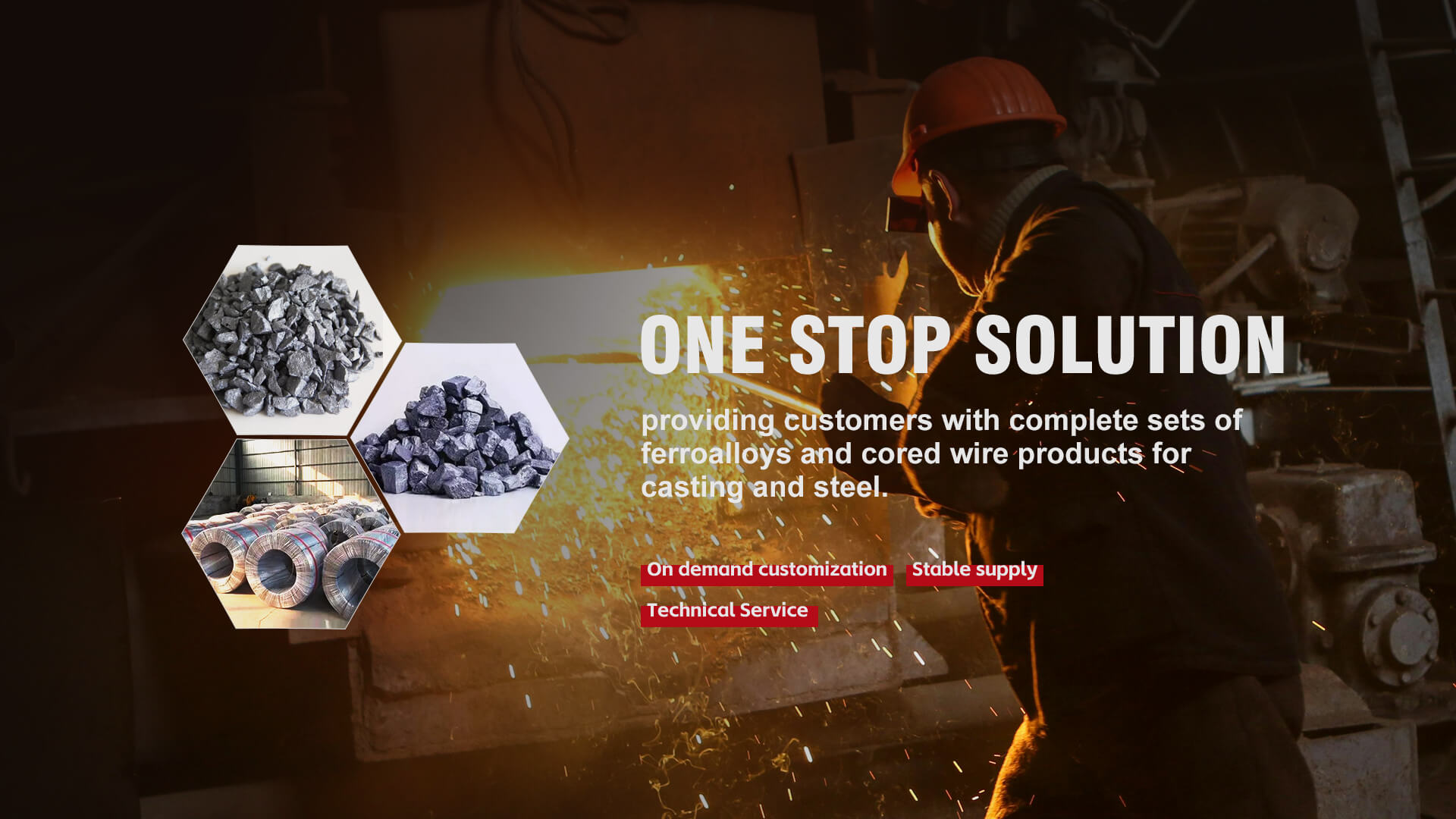

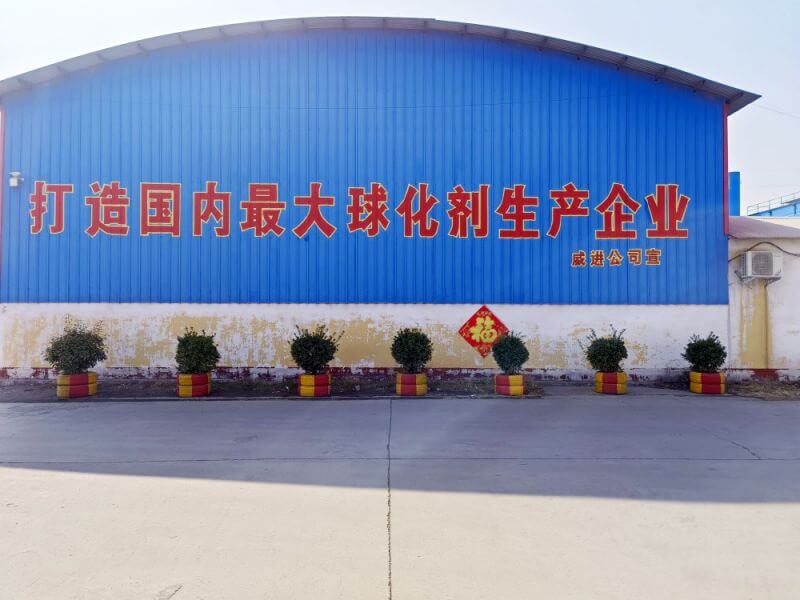

Anyang Weijin Casting Material Technology Co., Ltd. is engaged in the processing of steelmaking, casting ferroalloys, and core wire products using spheroidizing agents, inoculants, deoxidizers, and other materials. After more than twenty years of efforts and development, it has become a rapidly developing, large-scale, stable quality, and trusted ferroalloy industry advantage enterprise in China. Our company has passed the ISO9001-2015 quality system certification and was awarded the title of Contract abiding and Creditworthy Unit in Anyang City in 2018.The company has intermediate frequency electric furnaces and core wire processing lines, with an annual production of about 20000 tons of added alloys for steelmaking and casting, including spheroidizing agents (rare earth silicon magnesium alloys), inoculants (silicon, barium, calcium, strontium, etc.), desulfurizers, silicon calcium, silicon barium calcium, silicon aluminum alloys, silicon magnesium core wires, silicon calcium core wires, pure calcium wires, etc. With excellent processing equipment, strong technical strength, scientific processing technology, and unique formula, the ingredients of the processed products can be strictly controlled according to customer requirements, and have the characteristics of stable reaction and good absorption and fusion during use.The company is a ferroalloy export license enterprise approved by the Ministry of Commerce, and its products are currently sold to Guizhou, Fujian, Jiangxi, Jiangsu, Liaoning, Shanxi, and other regions. Mainly supplied to major steel and casting enterprises domestically. With stable quality and high-quality technical services, our products have won unanimous praise and trust from domestic and foreign customers.The competition in the future will become more intense. We will continue to strictly adhere to the requirements of the ISO9001:2015 quality management system, focusing on customer needs, and committed to providing updated and higher quality ferroalloy products and more satisfactory services for the steelmaking and casting industries.We are a research and technology oriented processing enterprise dedicated to the development of ductile iron materials. Our company adheres to Chinese virtues, integrates Western technology, and takes it as our responsibility to improve the quality coefficient of casting products and purify cast iron. We provide high-quality, precise, and cutting-edge casting materials and new technologies for customer service.The main products include: specialized spheroidizing agent for ductile iron manhole covers, new type of inoculant, silicon iron, silicon particles, slag removal agent, calcium aluminate refractory slurry, carburizing agent, core wire, desulfurizer, etc.Sincere cooperation, win-win cooperation, and a century of progress! Weijin Technology, which is honest, open, and innovative, warmly welcomes new and old customers to visit and negotiate cooperation!

-

20

Over twenty years

Industry technology precipitation

-

20000

Annual production of approximately 20000 tons of added alloys for steelmaking and casting

No matter what requirements or specifications of casting materials you need, we can

customize them according to your needs, and our rich resources provide you with product

supply options.

Photos about our workshop, packing and transportation